|

|

Tooling

| Tutorial

ATTENTION!!

As of 08-17-2022

Due to Joe Biden and the other Democrats further destroying our country's freedoms,

I no longer sell any jigs or 80% lowers.

|

Purchase and Shipping Terms

ATTENTION:

UPS CAN NOT DELIVER TO PO

BOXES!!

I

accept money orders, checks, bank cashier's check,

western union and cash money "greenbacks".

Personal checks will require 2 weeks

to clear the bank before package is

shipped.

To

place an order, simply print out the order

form and mail it along with the

payment. Click HERE

to print the order form. All

prices are in the order form.

Email

me when you send payment so I can keep

an eye out for it. For more

security, mail payment with delivery

confirmation. Alaska

customers, your package will be

shipped via USPS. My

email address is justin@cncguns.com

International

buyers - contact

me for buying details.

International buyers are required to

pay a flat rate of $50 insurance plus

USPS Express shipping and send payment

via Western Union. I

do not accept

international

money orders.

Due

to the ever increasing prying eyes of

"big brother" and the

growing number of anti-gun credit card

companies (especially paypal), I have

chosen to no longer accept online

payments. By mailing in your

payments, you won't have to worry

about your purchases and your personal

information being seen by a 3rd

party. The government is already

too big, don't allow them to see what

you are buying too.

|

|

Click images for larger photo

Click images for larger photo

|

|

MILLING

ADAPTER KIT

These

new AR15 lower receiver milling

adapters allow you to remove the

material from the fire control

area in AR type lower receivers. The adapters are sold

as sets. One adapter allows

you to drill the hole

locations and the other adapter

allows you to remove the material

using your drill press. With

these adapters you can remove the material from the fire control

pocket as well as the shelf inside

the fire control pocket. The

adapters have a hard anodized

coating that is gray in color

(shades of gray may vary).

This hard anodize finish give the

aluminum adapters very good wear

resistance.

The

milling adapters can be used to

finish AR15, AR10™

/ DPMS (0.308), and AR45 style

lower receivers.

They have also been used to

successfully complete Kevin's new

80% AR15 lower receivers.

Kevin has made it easier to

complete an 80% lower receiver by

leaving the fire control area

solid, drilling most of the side

holes and tapping the buffer tube

hole. Visit the tutorial

for more details on how to finish

Kevin's new 80%'ers. You can

get more details about Kevin's

80%'ers further down this page.

Also visit the tutorial

for

details on how to modify your

older style AR15 drilling jig so

the adapter kit will work with it.

Included

with each adapter kit:

-

(2) adapters

-

(4) bolts to secure the adapters

to the drilling jig

-

3/8 solid carbide endmill American

Made

-

Quick start instruction

guide

- NOTE:

The AR15 drilling jig is sold separately.

Drills

needed:

1/8

Drill -

# 60221413

3/8

Drill - # 81181240

7/16

Drill - #60221611

1/2

Drill (Optional) - #00647511

Get

ordering info at the top of the

page. Prices are in the

order form.

|

|

|

|

TRIGGER

SLOT MILLING ADAPTER KIT

If

you want a super easy and error

free way of cutting the trigger

slot in your lower receiver then

you need the trigger slot milling

adapter plate. This adapter

plate works just like the above

milling adapter kit for the fire

control pocket. You simply

drill through the guided holes,

flip the plate around and then use

the slot in the plate to guide the

included endmill to the exact

location. Visit the bottom

of this

tutorial for more information

on how to use this adapter plate.

This adapter plate kit isn't absolutely

necessary to finish a 80% lower

but it will make your life easier.

Included

with each adapter kit:

-

trigger slot milling adapter plate

-

special ground 1/4" solid

carbide endmill American

Made

-

Quick start instruction

guide

Drills

needed:

Letter

"L" Drill #01189125

Note:

The fire control pocket needs to

be finished before using this

adapter.

Get

ordering info at the top of the

page. Prices are in the

order form.

|

|

|

|

Click images for larger photo

Click images for larger photo

|

|

AR15 LOWER RECEIVER

DRILL JIG

The original CNC machined setup blocks / drill guide for completing your 0% - 80% (casting or forged)

AR15 lower receiver.

The blocks have a black

anodized finish. I enjoy helping people get started in this hobby, so let me know if you ever have any questions. YOU WILL NOT FIND THIS KIND OF SUPPORT ANYWHERE ELSE!!!

A great deal of research and design time was put into these blocks to make sure they were as user friendly as possible. These blocks will help hold the receiver flat and square while you finish the work needed to get your receiver machined into a firearm. The

blocks are machined to mil-spec

standards, so every hole is right

on the money. The jig

includes the drilled and tapped

holes for the optional milling

adapter kits (listed

above).

Applications

Using

this jig is as easy as 1-2-3; (1) Place the blocks on both sides of the receiver and loosely tighten the two bolts, (2) Put the assembly upside down on the edge of a flat table and use another flat surface to make sure the back of the receiver is coincident with the back surface of the blocks ~this step is for locational

purposes~ (these two location surfaces must be to finish specs before use), (3) Then simply tighten the bolts and you are ready to drill the side holes or do any other work that needs to be done on your receiver.

|

|

|

Bolt Catch Hole and Buffer Tube Area

This

AR-15 jig will also aid you in drilling the bolt catch hole as well. Simply slide the block with the slots (as seen in the photo) over the receiver and clamp them together with a C-clamp and you are ready to drill the bolt catch hole, nice and straight without worrying about a crooked hole and ruined

lower. To get the pistol grip hole finished just slide the pistol grip onto the receiver and mark where the hole should be drilled. Then place a 2

½" block under the receiver (as shown) to easily drill the pistol grip hole. This way of drilling the hole is

by far the easiest method.

You can also use

this AR15 jig to make sure you get that tricky buffer tube area

drilled and tapped the first time. These blocks will even help you drill the front detent pin and any other work on top or bottom of the receiver.

The jig is so EASY to use, that you can finish out your receiver using little more than a cordless drill with the proper drill bits. No matter what side of the receiver you need to machine or drill, these setup blocks will insure you hold your receiver flat and square every time.

The blocks have a black

anodized finish, so you will be

able to use these blocks many

times. This is the same

mil-spec anodized finish that

the military uses, so you know

it will last a very long time.

The blocks are shipped with a

quick start instruction sheet to assist you in using your blocks for the first time. You

can also view the tutorial at

this link CNC

Gunsmithing Jig Tutorial.

This

AR15 jig will save you time and

money. No more trashing a

receiver because you drilled a

hole off position or at an

angle. This is a must have for

finishing an AR-15 receiver the

EASY WAY! Get yours today.

Get

ordering info at the top of the

page. Prices are in the

order form.

Proudly Manufactured by:

|

|

|

I guarantee

this AR15 jig is the very best tool you will find anywhere. These have been tested and used to actually complete the receiver pictured. I designed and made these for beginner and professional home gun smiths and all who have used my tooling has nothing but positive comments!

NOTICE: All products and photos contained herein are the property of

jwh02017, and are copyrighted (patent in progress). The copying of

these images and/or reproduction of the products in any form are strictly prohibited without written consent from jwh02017. All violators will be charged to the fullest extent of US Copyright, Patent and/or Trademark laws.

|

|

|

|

|

|

AR10™

/ DPMS (.308) LOWER RECEIVER SETUP

DRILL JIG

Due

to the increase interest of the

.308 AR rifle, I have developed an

AR10™ / DPMS (.308) drill

jig. No longer will you have

to modify your AR15 jig in order

to complete a .308 AR lower

receiver. The AR10™ jig is

based on the exact same concept as

my AR15 jig so you can reference

the AR15 tutorial at the top of

the page for details on how to use

the jig. Please also reference

the AR10™ blueprint for holes that

differ from the AR15 lower

receivers.

The

AR10™ jig will work perfectly with

my AR10™ lower receivers.

However, if you are wanting to

complete a DPMS style lower

receiver, then you need to note

the following. The front and

rear take down pins and the bolt

catch detent hole are not in the

exact same location on the DPMS

and the AR10™ style lowers.

In order to drill the hammer and

trigger holes, use the proper size

drill or gauge and insert them

into the selector hole and mag

catch hole of the jig and

receiver. With these two

reference points, you can then

drill the hammer and trigger

holes. See GEN2 mod

below for the newest AR10 drill

jig that more easily accepts DPMS

style lowers.

The

AR15 milling adapter kits will work

perfectly with this .308 jig. So

it is now just as easy to remove

the material from the AR10™ and

DPMS lowers as what it has been

with the AR15 lowers.

GEN2

mod (see below)

I've

updated the drill jig so it's now

easier to use DPMS style lowers

with the jig. The right side

of the jig now has 2 extra take

down holes and they are marked

DPMS ONLY (see pic below).

These 2 holes are only to be used

with DPMS style lower receivers.

To locate a DPMS style lower in

the jig, simply take a couple 308

style take down pins (not

included) and insert them from the

back side into the holes marked

DPMS ONLY. Then locate the

receiver on the pins and clamp the

other side of the jig. (see pic

below). Please note the Armalite

and DPMS take down pins do no line

up. If you are using an

Armalite style lower then you must

ignore the 2 holes marked DPMS

ONLY. The 308 take down pins

are larger diameter and longer

than standard AR15 take down

pins. If you don't currently

have the take down pins, then you

can substitute them with the

proper size drills or dowel pin.

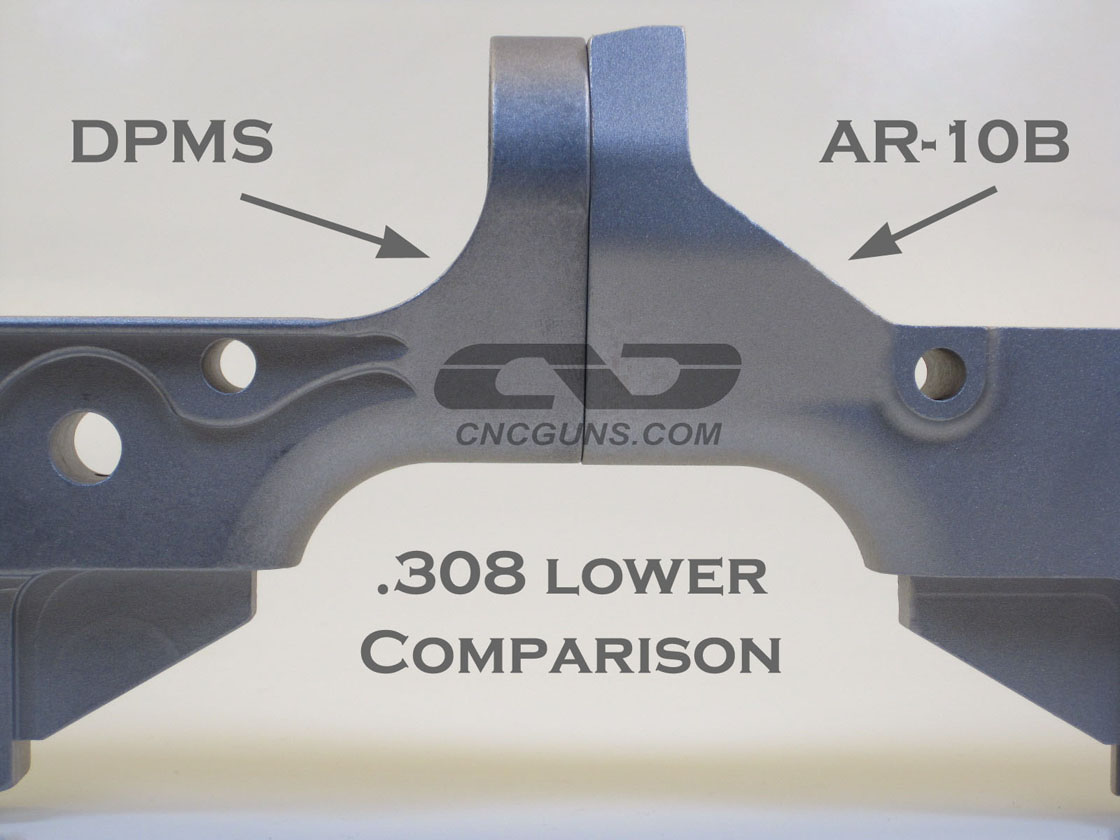

Reference

the image below for the difference

between Armalite and DPMS style

308 lower receivers.

Armalite has 2 different 308

designs. The AR-10B which

accepts M14 style mags and the

AR-10A which accepts pmag style

mags.

Get

ordering info at the top of the

page. Prices are in the

order form.

|

|

|

|

locks clamps mag magazine magazines

rif

le .223 5.56

Tutorial

Be

sure to check out the tutorials

on how to use

the cncguns jigs to complete an AR15

80% lower receiver. You might also find

the answer to your question on the forum

under the FAQ

section. If you still can't find

the answer to your question, feel free

to contact me. justin@cncguns.com

Drills

|

I have put together a list of the drills/tap you will

possibly need to purchase in order to complete your receiver. I don't sell these tools since you will be able to buy them cheaper from MSC www.mscindustrial.com

Below you will see the part number

of each tool. You may not

need every tool listed below

so be sure to check the tutorials

for the exact tools you will

need.

|

I

buy all the tooling for my shop from MSC. They have great quality and service. I would highly recommend using them instead of buying from somebody that is reselling the tools to complete the AR-15 receiver.

AR-15

Receivers

Terms

and Conditions All

products and photos contained herein are

the property of cncguns, and are

copyrighted and/or trademarked.

The copying of these images are/or

reproduction of my products in any form

is strictly prohibited without my

written consent. All violators

will be charged to the fullest extent of

US Copyright and Trademark laws.

Although I've had great using these

jigs, they come with no warranties or

guarantees. I am in no way

responsible for what is done with these

jigs or what they are used to

make. Prior approval is needed

before any product is returned.

There are no returns or refunds after 30

days from purchase date. There may

be a restocking fee up to 25% on any

returned products. Shipping

charges can not be refunded. Any

returned product must be in perfect

unused condition.

|

|